Whether collaborating with customers to review designs for machinability or reverse engineering a part for replacement, our talented machinists enjoy every opportunity to create highly engineered, thoughtfully designed machined parts and gears.

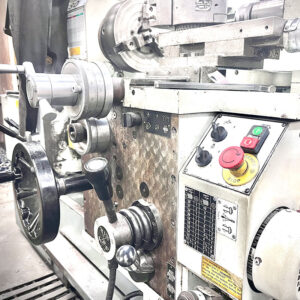

With solid equipment and even better people, we turn a variety of parts – ranging from small to large, nylon to stainless – with ease and precision.

Multiaxis mills, cutting-edge CAD/CAM software, and machinists with experience measured in decades, we tap, shape, bore, slot, drill, and mill to the tightest of tolerances.

If folks know us for only one thing, it’s likely gear cutting. With a range of shapers, cutters, hobbers amassed over a century, and the leading gear machinists in the region, we cut teeth well, really well, no matter bevel or spur, rack or pinion, miter or helical.

With nearly a dozen furnaces, we can thru and surface harden your precision parts for increased durability and consistency. We offer nitriding, annealing, tempering, and vacuum heat treating, air and oil quench, deep freezing and sand blasting.

Like our customers, we measure our success in tenths of thousandths, which means we grind (cylindrical and surface) a lot of parts to exacting standards.

Many of our more intricate parts require welding. We love seeing multiple parts come together harmoniously with a strong, clean weld. Whether TIG, MIG, or Stick, we wield a mighty weld.